1, cooling section and homogenization section

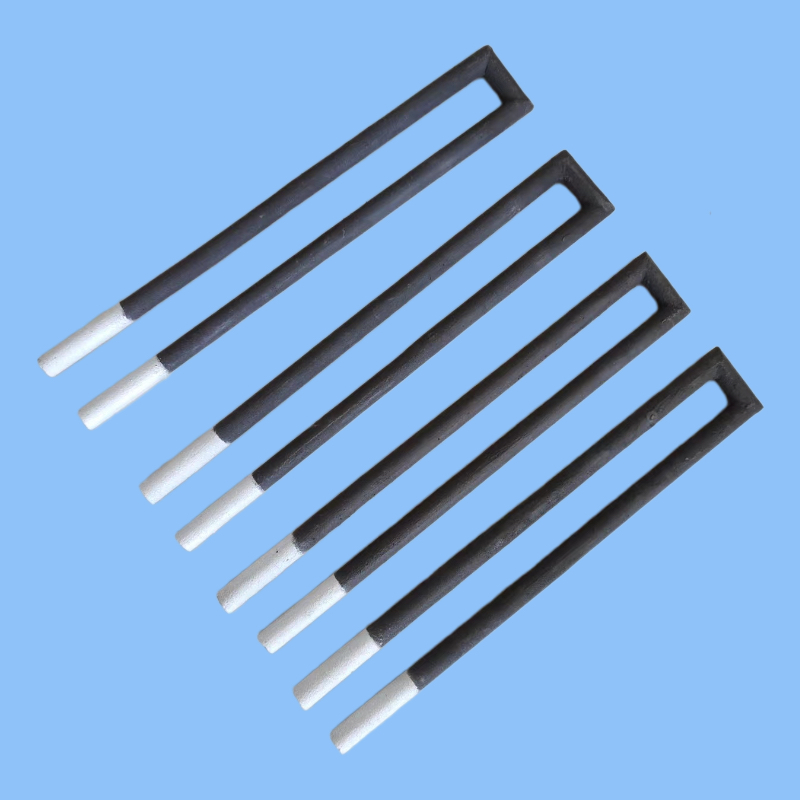

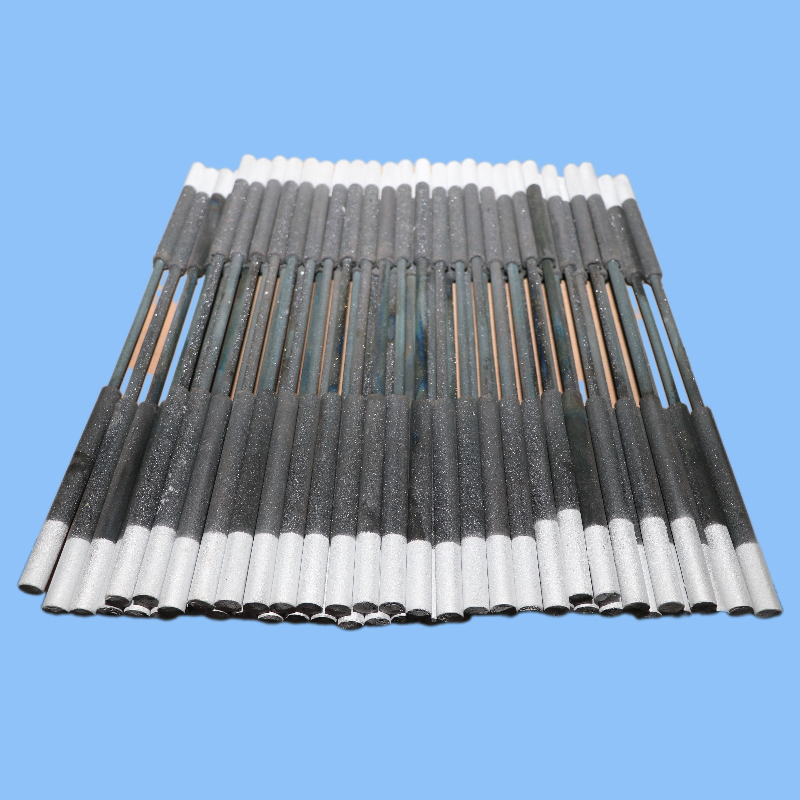

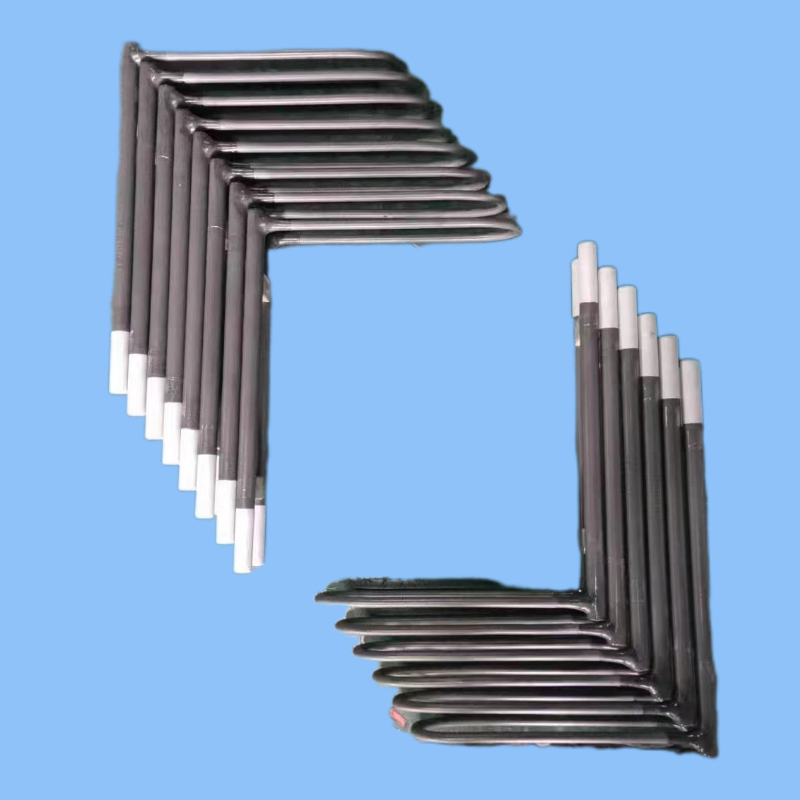

In the process of flowing through the cooling and homogenization section, the glass liquid should be uniformly cooled to the temperature suitable for molding. If no measures are taken, the heat dissipation on both sides of the material passage is more, and the heat dissipation in the middle part is less, which will lead to a large temperature gradient between the middle part of the glass and the two sides, that is, the temperature of the same section of the glass liquid is not uniform, so that the viscosity of the glass liquid is inconsistent, which directly affects the quality of the molding. In order to make the feed liquid temperature consistent, on the one hand, the cooling hole is reserved in the cooling section, and the heat dissipation in the middle part of the cooling section is adjusted by adjusting the opening of the cooling hole, so that the temperature is uniform; On the other hand, the use of special silicon carbon rod auxiliary heating to achieve. The silicon carbon rod is generally uniformly arranged above the glass liquid in the feed channel, maintains a certain distance from the glass liquid, and radiates downward for heating. In order to ensure that the two sides of the feed channel are heated and the middle part is not heated, the glass feed channel industry special silicon carbon rod five rods (that is, double heating body silicon carbon rod) are generally selected. It is composed of two identical heating bodies and three cold ends welded by a special process, that is, the indirect cold end of two heating bodies, the total length of the three corresponds to the width of the material channel (in the imported material channel using double-threaded silicon carbon rod) because the middle part of the silicon carbon rod does not heat or less heat and is heated near the side wall, coupled with a reasonable design, It can ensure that the temperature of the liquid glass drops evenly in the flow. In the design of the feed path, some manufacturers also choose equal diameter silicon carbon rod (that is, three-section silicon carbon rod), which is welded by a heating body and two cold ends.

Three silicon carbon rods are used to heat both the glass liquid and the two sides of the wall, which can ensure the temperature of each section of the feed channel and supplement the heat dissipation of the side wall, but the homogenization effect is far less than that of five silicon carbon rods. Whether three or five rods are selected, the homogenization effect is determined by the structure of the feed channel and the heating of the silicon carbon rod, while the final temperature of each section of the feed channel is controlled by the control system.

2, basin section

After the glass liquid flows through the homogenization section, the temperature uniformly drops to a certain appropriate value, if the temperature at the basin is not controlled, it is still difficult to ensure that the drop has a constant and uniform temperature, so that the temperature is too high or too low will affect the shape of the drop, and ultimately affect the molding quality of the glass container. Therefore, the scientific method is to control the basin separately. Basin heating generally has the following two forms:

(A) Two gun type silicon carbide rods and one three-section silicon carbide rod are used to surround the material basin for heating.

(B) Two trough silicon carbon rods and one three-section silicon carbon rod are distributed around the material basin, and the material basin is heated.

19521493131

19521493131