Silicon carbon rods and silicon molybdenum rods, as a new type of electric heating element, are widely used in various types of modern electric industrial kilns. Modern industrial kilns are based on the development of modern industry. As a widely used thermal equipment, they can be divided into continuous and intermittent types in operation, and flame type and electric type in terms of the heat source used. The principle of an electric furnace is to use electric heating elements such as electric wires, silicon carbon rods, and silicon molybdenum rods to convert electrical energy into heat energy, relying on the characteristics of conductive electric heating elements that generate electricity. Through radiation and other heat transfer methods, the temperature of the products in the furnace is raised, and the sintering is completed according to the predetermined sintering conditions. Electric heating kilns have been widely used as heating equipment in various industries in recent years, especially with the development of industrial environments worldwide in the energy industry, refractory material industry, heating materials, and the continuous progress of automatic electrical control. Electric heating industrial kilns have made rapid progress.

Compared to flame kilns, electric kilns have the following characteristics:

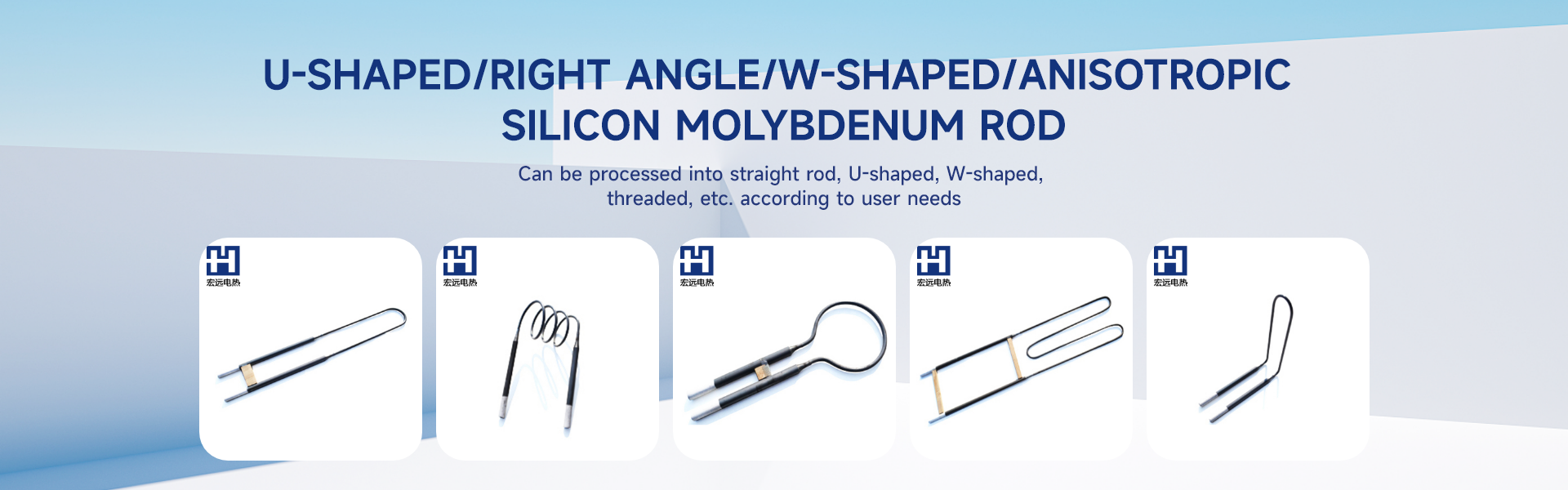

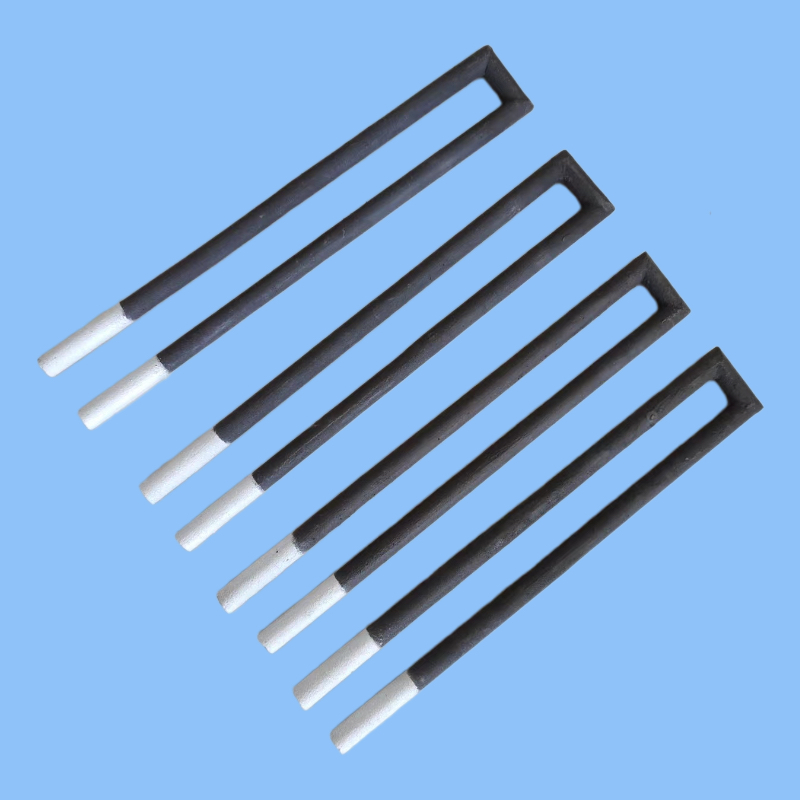

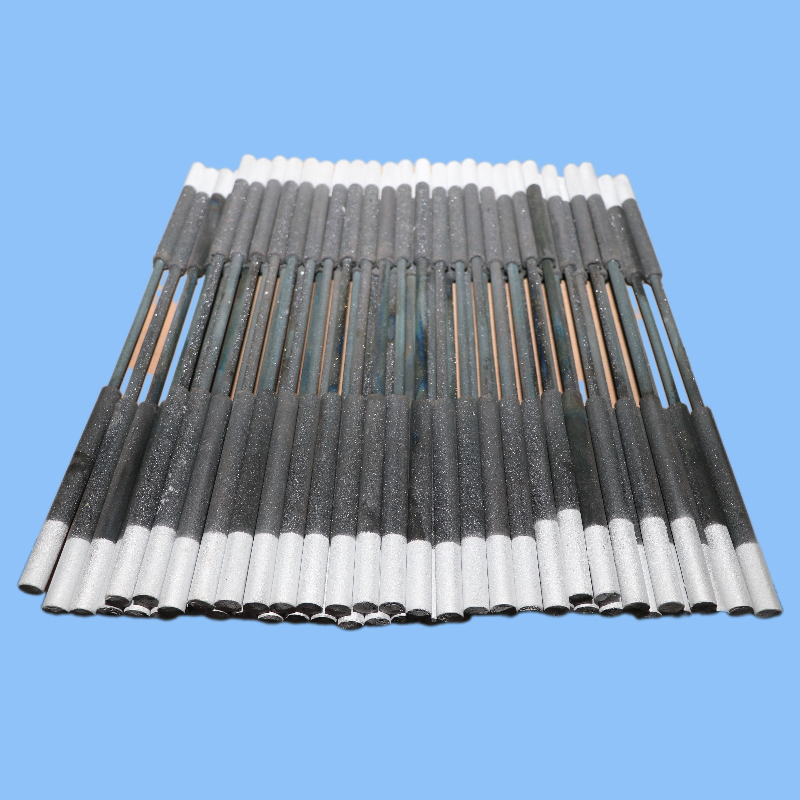

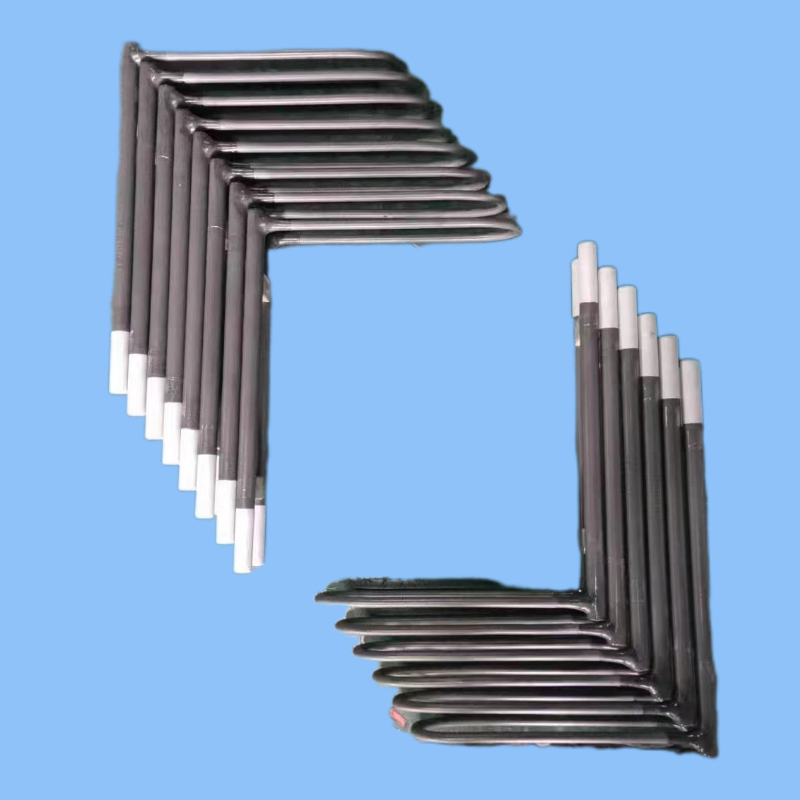

**From the design steps of the kiln, the flame type kiln relies on the combustion of fuel as the heat source, so designing this type of kiln requires relevant calculations of fuel and combustion equipment; At the same time, due to the need to supply combustion air and exhaust combustion products, relevant ventilation equipment should also be considered. Electric heating furnaces require the calculation of the required heating power based on heating requirements and the internal dimensions of the furnace. Suitable heating elements are selected based on different heating temperatures (electric heating wires are mainly used below 800 degrees Celsius, silicon carbon rods are mainly used between 800 degrees Celsius and 1400 degrees Celsius, and silicon molybdenum rods are mainly used between 1400 degrees Celsius and 1800 degrees Celsius). Then, the size and quantity of heating elements are determined based on the furnace space requirements and the heating power allocated to a single heating element, *Based on the calculated data, choose the power supply and control equipment reasonably.

**From the perspective of operation and use, the temperature of the electric kiln is easy to control, and its structure is relatively small, so the firing quality of the product is good. Based on this advantage, industries with high requirements for sintered products will use electric heating industrial kilns that use silicon carbon rods, silicon molybdenum rods, or a combination of both for sintering related products. For example, sintering kilns for various magnetic materials, glass products, industrial ceramic devices, and the rapidly developing positive and negative electrode materials of lithium batteries mostly use silicon carbon rods and silicon molybdenum rods as heating sources.

Thirdly, from the perspective of cost, the auxiliary electrical equipment of electric heating kilns is relatively complex, and high-quality refractory materials are relatively expensive. Silicon carbon rods and silicon molybdenum rods, which serve as heat sources, are also consumables. The electricity cost for the operation of the kiln is relatively high, resulting in a relatively high cost of using electric heating kilns. In addition, many small factories in China currently produce silicon carbon rods and silicon molybdenum rods with relatively cheap raw materials, outdated production processes and equipment, and loose product quality management, resulting in frequent fracture and rapid aging of silicon carbon rods and silicon molybdenum rods during use, further increasing the cost of using related electric furnaces.

Therefore, for industrial products that require the use of electric furnaces for sintering, the selection of high-quality control equipment, refractory materials, and heating elements by electric furnace manufacturers and kiln users is an effective way to reduce production costs, improve production efficiency, and improve product quality. In terms of research and development and production of silicon carbon rods and silicon molybdenum rods, Zhengzhou Hongyuan Electric Heating Element Co., Ltd. has gone through more than 30 years of effort and development. Its silicon carbon rods and silicon molybdenum rods are rare products in China that can achieve the same quality as international well-known products. Especially for relatively special heating and usage environments, Hongyuan Electric Heating has a unique production process and proprietary technology, which enables its products to have a more stable operating state and long service life compared to other companies products. It can effectively avoid common problems such as fracture of heating elements in different parts during use, unstable current during use, and rapid aging rate. At the same time, the complete after-sales technical service of Hongyuan Electric Heating is also the foundation and guarantee for long-term cooperation with customers.

19521493131

19521493131