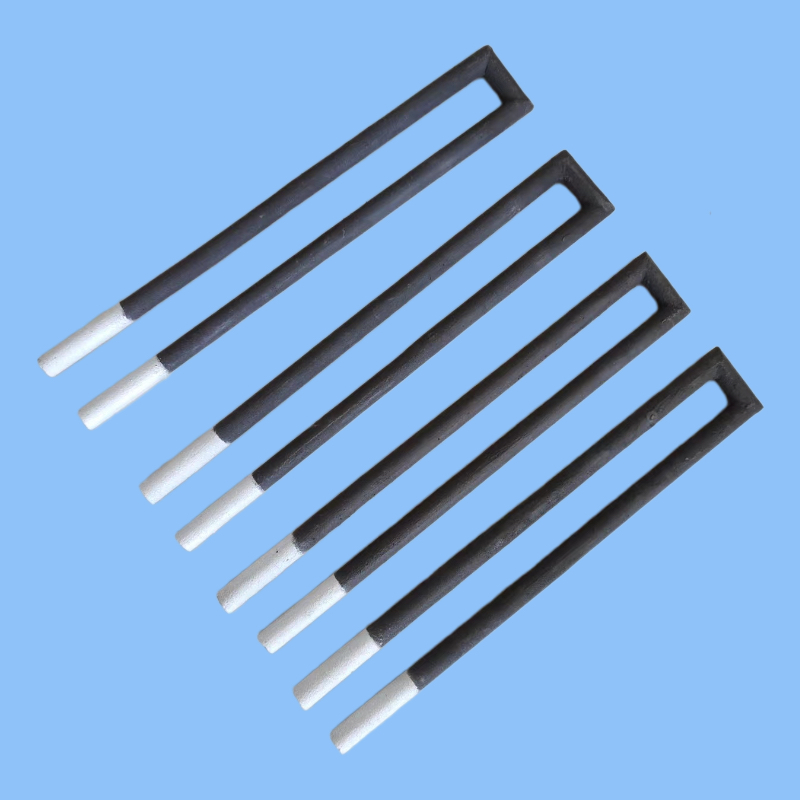

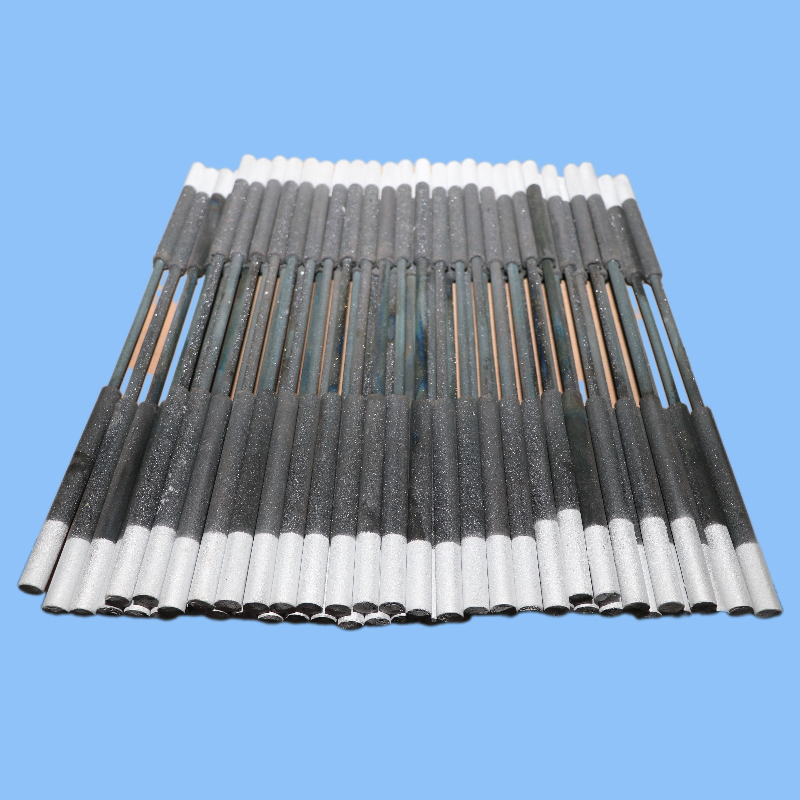

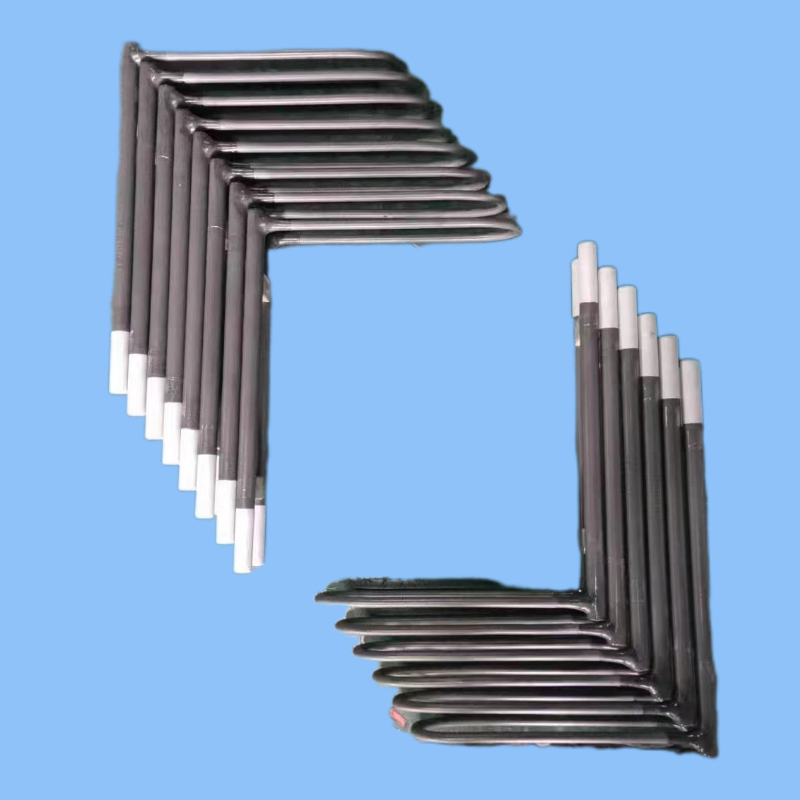

There are many specifications for equal diameter silicon carbide rods, which are commonly used in silicon carbide electric heating components, with diameters ranging from 8mm to 60mm. The commonly used diameter of silicon carbide components is 12-45mm. The length of the heating part is generally between 80-200mm. The company customizes according to needs and provides answers to relevant technical questions. Welcome to inquire and order.

Silicon carbon rods are suitable for continuous or intermittent kilns, but the former has a longer service life. This is because the silicon carbide rod protective film, the silicon dioxide film, is prone to abnormal expansion, contraction, and detachment near the critical point of crystallization (270 degrees Celsius), while the intermittent kiln has a large number of furnace shutdowns and heating times, which will repeatedly damage the silicon dioxide film, accelerate the oxidation and aging of the silicon carbide rod.

Precautions for installation and use of some silicon carbide rods:

1. Silicon carbon rods are hard and brittle in texture, and are prone to fracture under severe vibration and impact. Therefore, during transportation and installation, it is necessary to handle the workpiece with care. When handling and placing the workpiece, it should not touch the silicon carbide rods distributed around it, nor should it cause severe vibration of the electric furnace.

2. Silicone carbon rods should be stored to prevent moisture. Because moisture can easily cause the aluminum layer at the cold end to decompose and fall off, resulting in a higher contact resistance between the cold end and the fixture, and the silicon carbide rod is prone to cracking after being energized.

3. Newly built furnaces or electric furnaces that have not been used for a long time should be dried before use, and old rods or other heat sources should be used for drying.

When replacing silicon carbide rods, they should be selected with a resistance similar to that of the silicon carbide rods running in the furnace. If necessary, the entire furnace of silicon carbide rods should be replaced, which is beneficial for improving the service life of the silicon carbide rods. If the resistance value of the removed silicon carbide rods is appropriate, they can also be replaced for use in the middle and later stages of electric furnace operation.

During installation, silicon carbon rods should not come into contact with insulation materials and should be separated by high-temperature insulated porcelain tubes. To avoid arcing due to electric leakage and causing wall melting.

During the operation of the high-temperature electric furnace, it is not allowed to open the furnace door arbitrarily, as it will accelerate the oxidation of the silicon carbon rod being heated.

7. Silicon carbide rods can cause corrosion when in contact with alkali, alkali metals, alkaline oxides, silicates, borides, sulfuric acid, etc. Water vapor also has a strong oxidizing effect on it, and gases containing a large amount of hydrogen can also decompose silicon carbide rods at high temperatures. We also need to prevent chemical reactions between silicon carbide rods and harmful gases.

8. To ensure uniform furnace temperature and load bearing capacity of the rods, assembly should be carried out before installation. Silicon carbon rods with the same or similar resistance values should be connected together, and the resistance deviation of each group of silicon carbon rods should not exceed 10%.

9. When selecting silicon carbide electric heating elements, it is necessary to ensure that the length of the heating part of the element is not greater than the width (height) of the furnace. If the heating part extends into or touches the furnace wall, it is easy to burn the furnace wall. The length of the cold end of the silicon carbide rod should be equal to the thickness of the furnace wall plus the length of the cold end extending out of the furnace wall. The extended length of the cold end is generally 50-150mm, in order to cool the cold end and connect the fixture.

10. The inner diameter of the installation holes on both sides of the furnace (the inner diameter of the heat-resistant insulating ceramic tube) should be 1.4-1.6 times the outer diameter of the cold end, and the two holes should be concentric. If the furnace holes are too small or filled with asbestos or aluminum silicate fibers too tightly, it will hinder the free expansion and contraction of the silicon carbon rod and cause the rod to break at high temperatures. When installing, the silicon carbide rod should be able to rotate freely 360 degrees.

11. The wiring method of silicon carbon rod components can adopt parallel, series, angular, star, and other forms of wiring; However, parallel connection is superior to series connection, as it can adjust the factors of load imbalance, while multi branch series connection exacerbates the factors of imbalance and increases the working voltage.

12. Equip the silicon carbide rod with a pressure regulating device. At the initial stage of power transmission, the voltage is half of its normal working voltage, and gradually increases after stabilizing for a period of time. This way, the silicon carbide rod will not break due to rapid heating.

13. After wiring, it is necessary to carefully check whether the connection strip is firmly in contact with the rod. If the contact is poor, it may cause arcing after power on, resulting in the entire rod being scrapped.

19521493131

19521493131