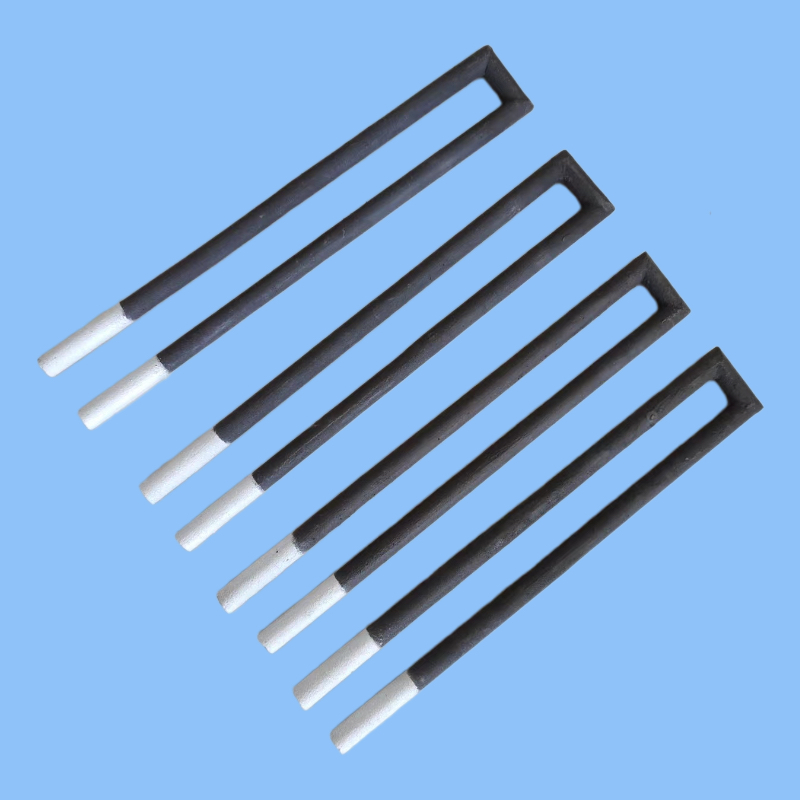

①, In order to ensure that each silicon carbon rod can be in a normal and ideal working state, the resistance value of the whole batch of silicon carbon rods is determined before installation, and it is classified, and the resistance value is similar to that of the same adjustment area, so that the working resistance is similar.

②, in order to test whether each silicon carbon rod electric heating element is working well, the current can be measured one by one by a clamp ammeter during the power test. The same area requires similar currents under equal voltage, and the deviation does not exceed 10%, if the individual current is too large, it indicates that the resistance value is too small. If the current is too small, either the resistance is too large or the pin is poorly pressed. If there is no current, it may be that the silicon carbide rod heating element has broken, and it should be further checked and replaced.

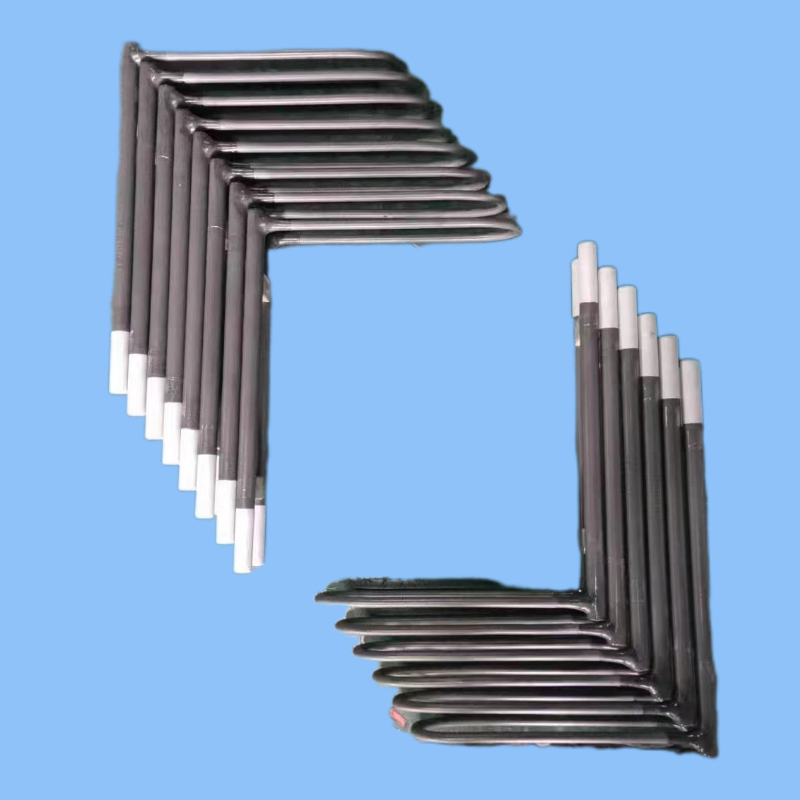

③, the silicon carbon rod electric heating element is brittle and easy to break, especially in the threaded position of the most vulnerable, installation should be particularly careful, gently handle, installation should pay special attention to never allow unilateral force, if necessary, the application of heat-resistant steel pipe cover silicon carbon rod gently push into and then pull out the steel pipe sleeve, install the sheath fixed.

④, In order to prevent the interaction between the silicon carbon rod heating element and the refractory material of the superstructure, the pins of each element are insulated with ceramic fiber sleeve, which not only plays the role of electrical insulation but also plays the role of fixing the silicon carbon rod.

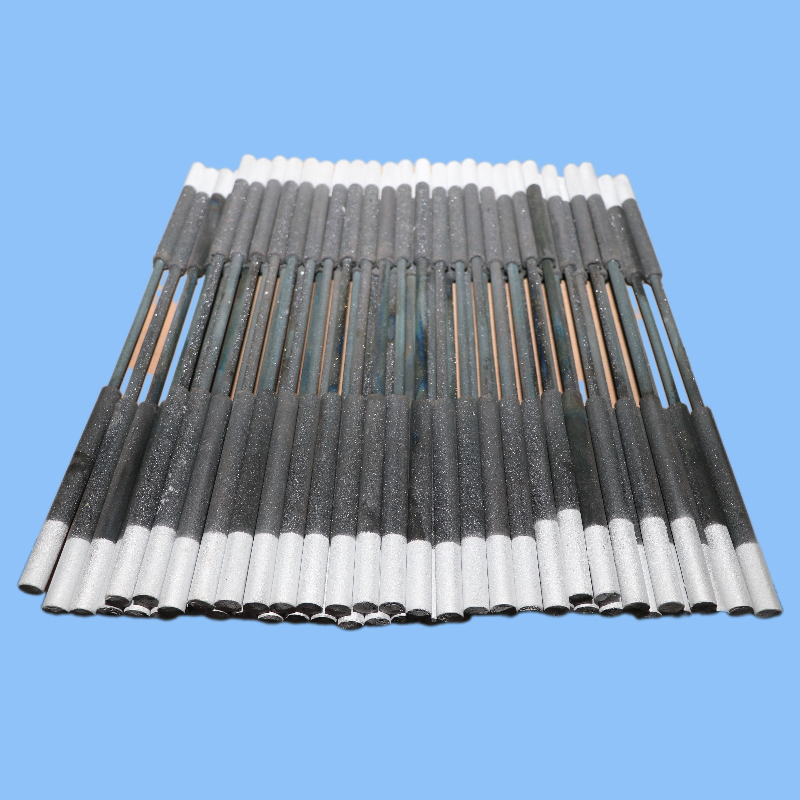

⑤, the use of silicon carbon rod in the kiln, the maximum temperature in the furnace can reach 1500℃. The life of silicon carbide heating elements is generally 3 to 4 months, up to 6 to 8 months.

⑥, the silicon carbon rod used in the feed channel, in order to extend the life of the silicon carbon rod heating element. The structure of the material track can be improved, and the material track can be separated from the working pool by blocking bricks, and the atmosphere of the material track can be strictly controlled.

⑦, reduce the impact of temperature. The aging rate of silicon carbide components is proportional to the use temperature, the higher the use temperature, the faster the aging, the shorter its life.

⑧, reduce the surface load density by adjusting the power load applied to the silicon carbon rod element. If the use of smaller loads and lower surface load density, although the temperature in the kiln is high, it can also maintain a considerable long life, which can be achieved by changing the number of silicon carbon rod components installed, or changing the specifications of the components to adjust the size of the heating surface. The surface load density is inversely proportional to the furnace temperature. The higher the furnace temperature is, the smaller the allowable surface load density is. Overload use will cause overheating decomposition of silicon carbide components, resulting in the surface of the heating part falling off and burning. In order to ensure the life of the components, it is not necessary to use the electric heating element under overload conditions, and its value is generally controlled at 6 ~ 8W/cm2.

⑨. After the silicon carbon rod electric heating element is used for a certain time, due to the increase of resistance value, the voltage needs to be increased to compensate for the loss of increased resistance, so the transformer needs to have a certain voltage regulation range; For kilns and feedways in continuous operation, the voltage adjustment range is 0.7 to 2.5V(V refers to the initial voltage used by the silicon carbide rod element). The service life of silicon carbide components can be extended by pressure regulation.

⑩ The wiring method of silicon carbon rod components can be parallel, series, corner, star and other forms of wiring. But the parallel is superior to the series, the parallel can adjust the load imbalance factor, and the multi-branch series will increase the imbalance factor, improve the working voltage. In order to prolong the life of silicon carbon rod components and ensure safe use, it is necessary to avoid using multiple series.

11, silicon carbon rod fragments fall into the glass liquid will cause bubbles, this is because silicon carbide has a strong reduction effect, will be dissolved in the glass liquid gas and glass components of the chemical reaction. Therefore, the incomplete silicon carbon rod fragments must be taken out, but in general, the silicon carbide rod will only break and not break.

12, the furnace gas contains a lot of sulfur, sodium, boron and other oxides, will react strongly with the silicon carbon rod, within a few days will make the whole rod fat and damaged. When using the silicon carbon rod heater, the feed path must be completely separated from the flame space of the working pool. In general, due to the low volatile content in the feed channel, the influence on it is very small.

19521493131

19521493131