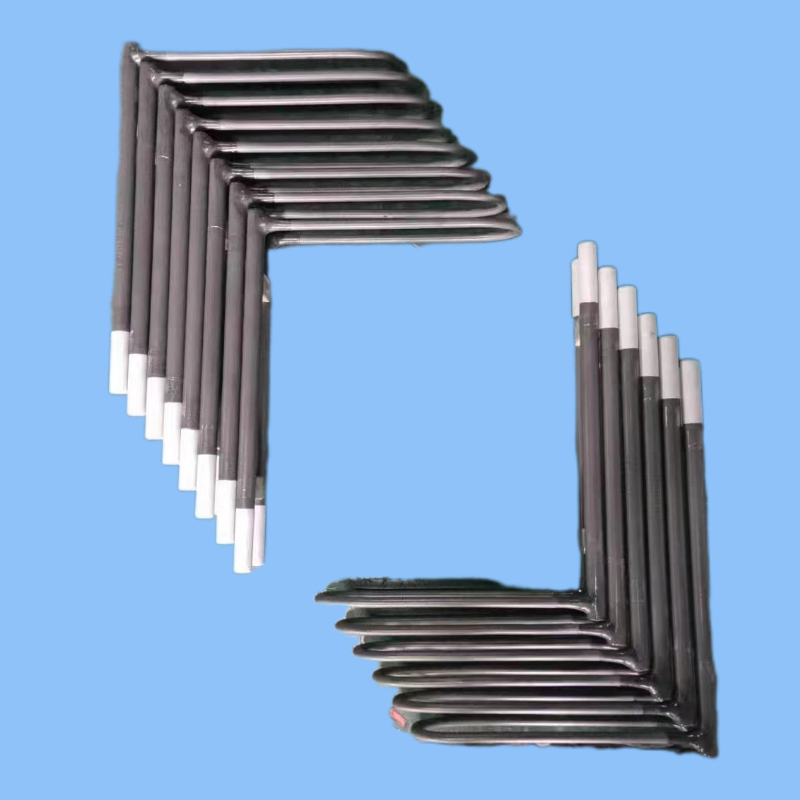

1.Check the resistance (Ω) value marked on the cold end of the silicon carbon rod before installation and use. If the writing is unclear, it must be re-tested. The test method is to measure the voltage and current measured when the silicon carbon rod is heated to a high temperature of 1050℃, and the resistance is determined by Ohm's law.

2. when the silicon carbon rod is used, each group of rods should be configured with high temperature resistance, and the allowable difference of the electrical value of the resistance is: ≥φ12mm rod resistance, resistance tolerance is ≤0.2Ω, ≤φ8mm rod resistance, resistance tolerance is ≤0.5Ω.

3. When the rod passes through the rod holes on both sides of the furnace wall (or above and below), it should be freely rotated 360 degrees to prevent forced installation and beating, and the iron pipe with the diameter of the rod can be installed before loading the rod.

4. the use of silicon carbon rod must be configured with a voltage regulator or thyristor regulator and voltage, ammeter and temperature automatic control instrument. In the process of use, due to the oxidation of the rod, the resistance is gradually increased, in order to maintain the normal temperature of the furnace, the use of voltage should be increased, when the voltage is increased to the maximum limit of the voltage used still can not meet the requirements, the furnace can be stopped to change the connection mode of the rod and continue to use.

5. when the new furnace starts to power, in order to prevent the rod from breaking, 1/2 of the rated power of the electric furnace should be air-sent for a period of time, and then gradually increase the voltage after everything is normal, according to the heating specification of the electric furnace, so as not to break the silicon carbon rod due to too high power.

6. the new furnace or the electric furnace (kiln) that has not been used for a long time, must be oven (kiln) before use, oven (kiln) as far as possible with old rods or other heating elements.

7. it is strictly prohibited to use silicon carbon rod overload, such as rod breakage or rod uneven heating, local incandescent or dark red phenomenon, which shows that the aging of the rod is inconsistent, a section of resistance difference is too large, should stop the furnace repair and replace the rod, it is best to replace all the new rod, such as replacing part of the new rod or a single rod will be due to the new rod resistance and used rod resistance match is not suitable, Lead to load imbalance, furnace temperature is not uniform. Due to the large resistance difference, the bar temperature difference is large, which will seriously affect the service life.

8. If there is water discharge during the heating process when the device or material is fired, the resistance furnace (kiln) should be left with an exhaust hole in order to remove the water or other exhaust gas in the furnace (kiln), so as not to affect the service life of the rod.

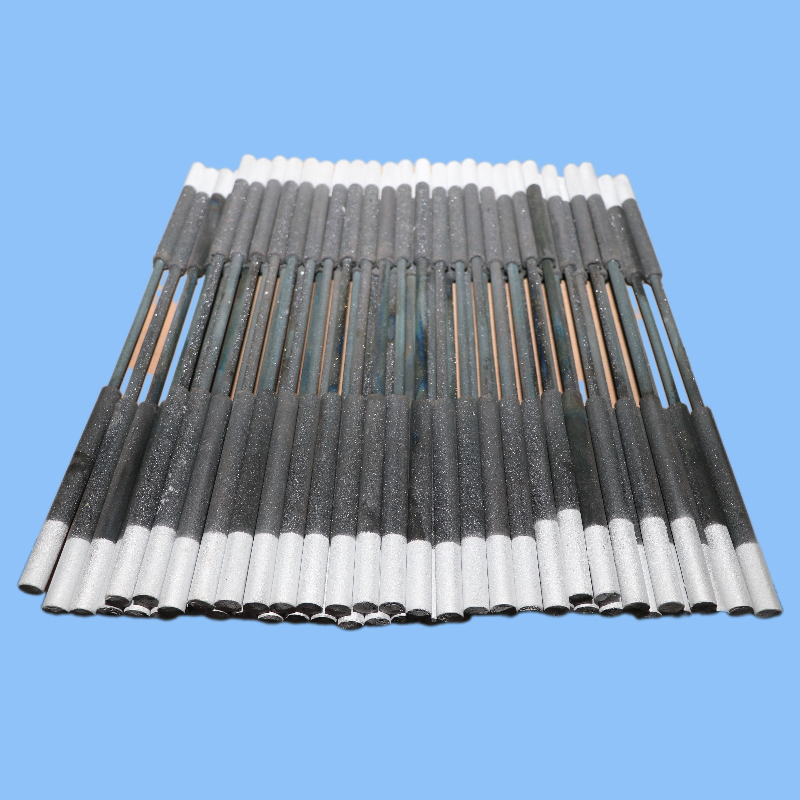

9. the storage process of the bar, pay attention to moisture. If it is found that the bar end of the spray aluminum metamorphic delixification, after surface treatment can be re-sprayed aluminum. If there is no aluminum spray condition, several layers of aluminum foil can be wrapped in the rod spray aluminum section.

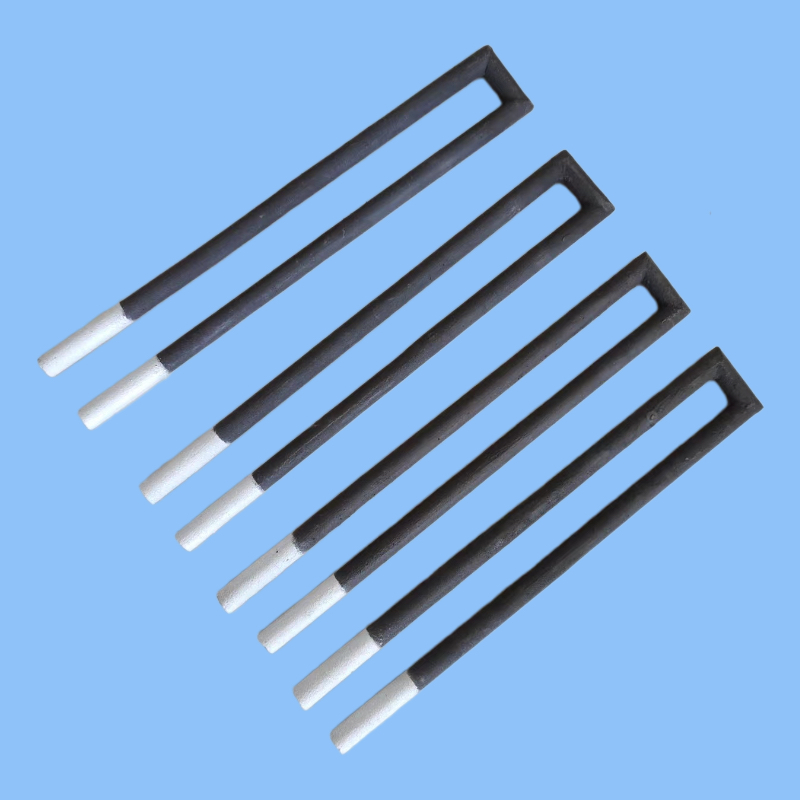

10. The silicon carbon rod is hard and brittle, and should not be careful when transporting, unpacking, installing and replacing. Handle lightly, gently, strictly prevent mechanical beating, so as not to break the rod.

19521493131

19521493131