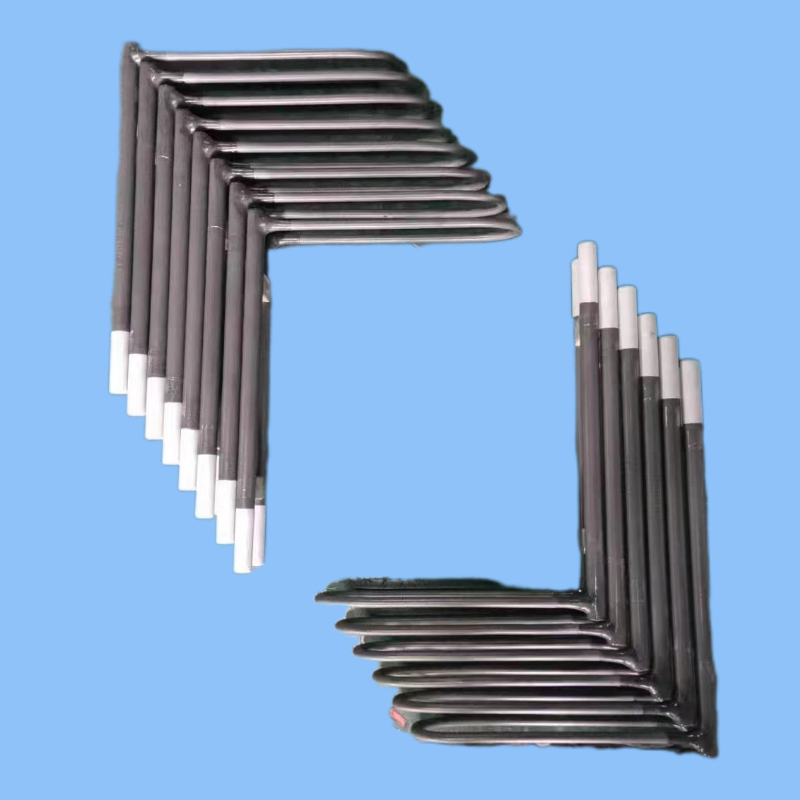

The main component of silicon carbide rod is silicon carbide, which is an artificial abrasive made by humans. Usually, silicon carbide is divided into two types: black silicon carbide and green silicon carbide, with a higher purity of green silicon carbide. Silicon carbide has relatively stable properties and does not react with any acids. However, at around 1300 degrees Celsius, it can undergo chemical reactions with alkalis and alkaline oxides. In addition to being used in the abrasive industry, silicon carbide is also used in the electrical industry to produce silicon carbide electric heating components - silicon carbide rods - due to their ability to conduct electricity, heat, and have a long service life. Therefore, the chemical properties of silicon carbide rods are very similar to those of silicon carbide.

Antioxidant properties of silicon carbide rods

After heating with electricity, the temperature of the silicon carbide rod will rapidly increase. Generally, when the temperature of the rod body reaches 800 degrees Celsius in the air, oxidation reactions begin to occur on the surface. As the temperature continues to rise to 1000-1300 degrees Celsius, the heating part of the silicon carbide rod will react with the air to produce carbon dioxide and silicon dioxide. Silicon dioxide will condense on the surface of the silicon carbide rod, forming a dense protective film. When the temperature of the rod continues to rise to around 1550, the thickness of the protective layer will become thicker due to the continuous production of silica, which can isolate the silicon carbide rod and air, forming effective protection for the rod. Thus, the oxidation rate of the silicon carbide rod begins to decrease. However, the silicon dioxide protective layer also has a certain melting point. If the rod body continues to heat up to 1600 degrees Celsius or above, the silicon dioxide protective film will undergo reactions such as detachment due to excessive temperature, and then the oxidation rate of the silicon carbon rod will be increased again. During use, this situation should be avoided as much as possible, and the structure of the resistance furnace or industrial electric furnace should be reasonably designed. During the installation of the silicon carbide rod, attention should be paid to the position of the rod body to avoid excessive temperature caused by local high temperatures or other electrical errors during use, which greatly reduces the service life of the rod body.

19521493131

19521493131