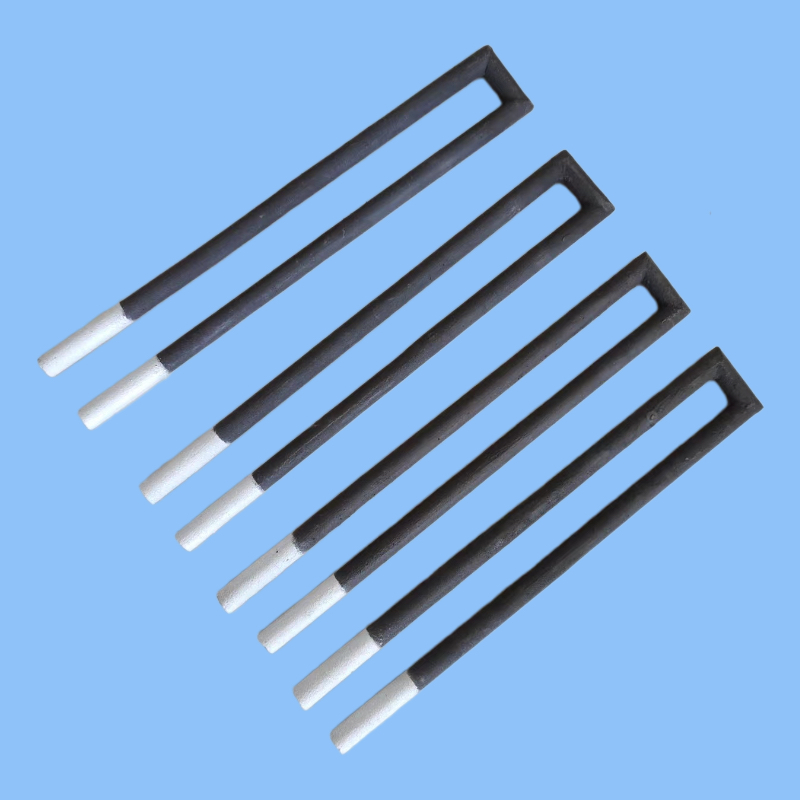

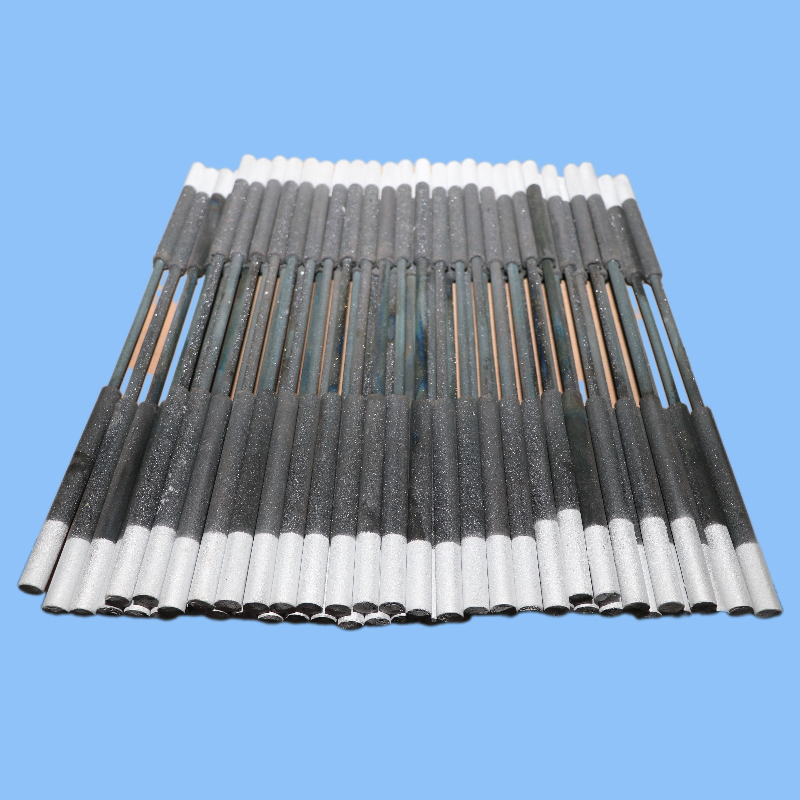

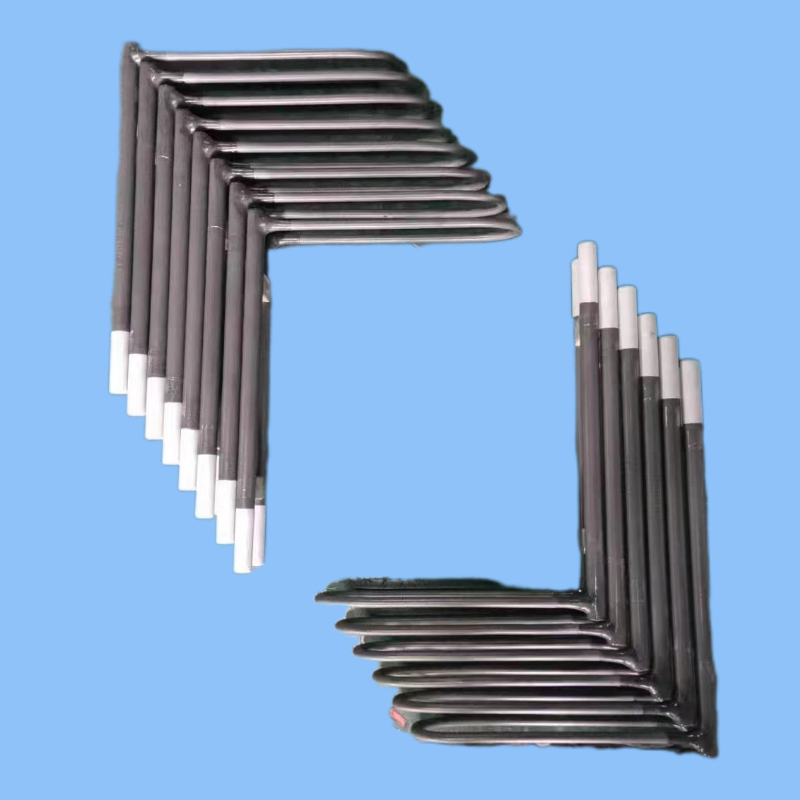

Equal diameter silicon carbon rods are commonly used heating rods in industrial production, customized according to demand, with a diameter of 12-60 millimeters. They are mainly used in powder metallurgy, glass industry, ceramic industry, refractory materials, lithium battery industry, semiconductor, scientific research, casting industry and other fields. They are tunnel kilns, roller kilns, glass kilns, vacuum furnaces, push plate furnaces, trolley furnaces, box furnaces, muffle furnaces, smelting furnaces, etc, Electric heating elements for various heating equipment such as experimental furnaces. Solid silicon carbon rods and coated silicon carbon rods can also be customized according to needs.

Silicon carbon rods can be wired in parallel, series, angular, star, or other forms; However, parallel connection is superior to series connection, as it can adjust the factors of load imbalance, while multi branch series connection exacerbates the factors of imbalance and increases the working voltage. Silicon carbide rods are generally used in combination with series and parallel wiring. In order to ensure that each silicon carbon rod can be in a normal and ideal working state, the resistance value of the entire batch of silicon carbon rods is measured before installation, and they are classified. Those with similar resistance values are installed in the same adjustment area, so that their working resistance is similar. Reduce the impact of temperature usage. The aging rate of silicon carbide components is directly proportional to the operating temperature. The higher the operating temperature, the faster the aging and the shorter its lifespan. By adjusting the power load applied to the silicon carbide rod components, the surface load density is reduced. If a smaller load and lower surface load density are used, even though the temperature inside the kiln is high, it can maintain a considerable lifespan. This can be achieved by changing the number of installed silicon carbon rod components or changing the specifications of the components to adjust the size of the heating surface to achieve a hard and brittle texture of the silicon carbon rod, which is prone to fracture under severe vibration and impact. Therefore, special care should be taken during transportation and handling with care. After wiring, it is necessary to carefully check whether the connection strip is firmly in contact with the rod. If the contact is poor, it may cause arcing after power on, resulting in the entire rod being scrapped.

19521493131

19521493131